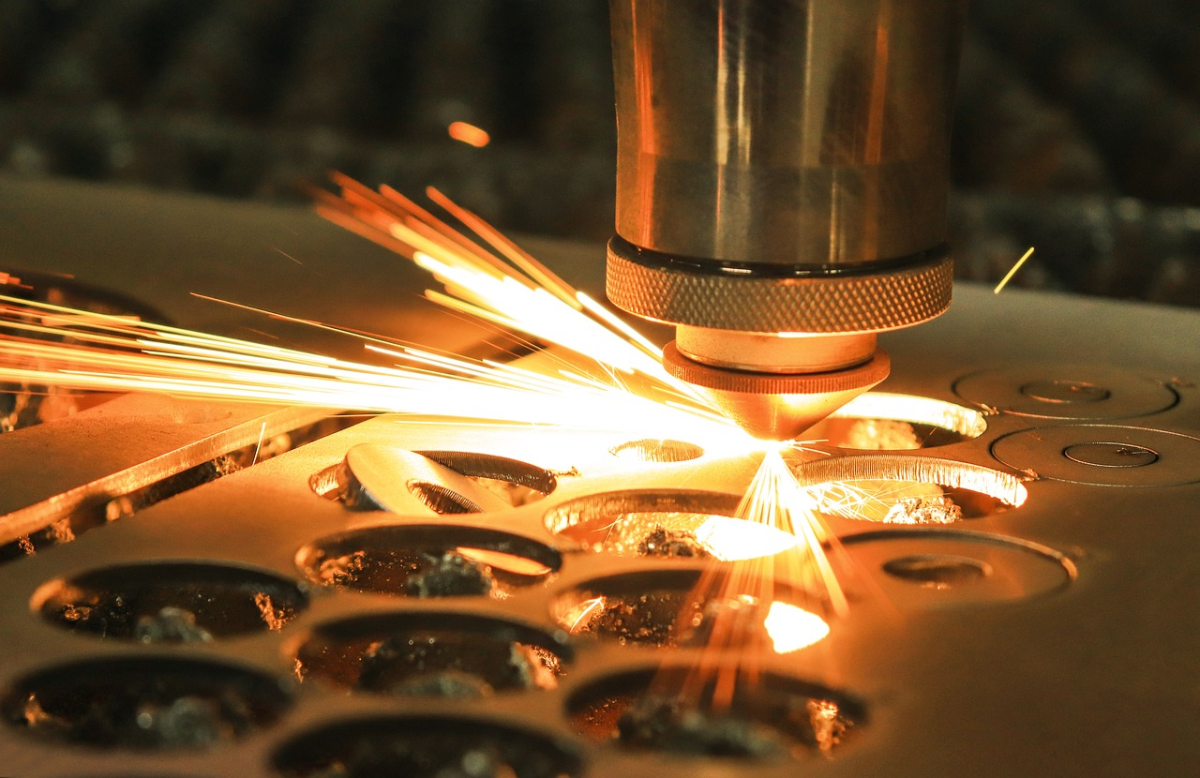

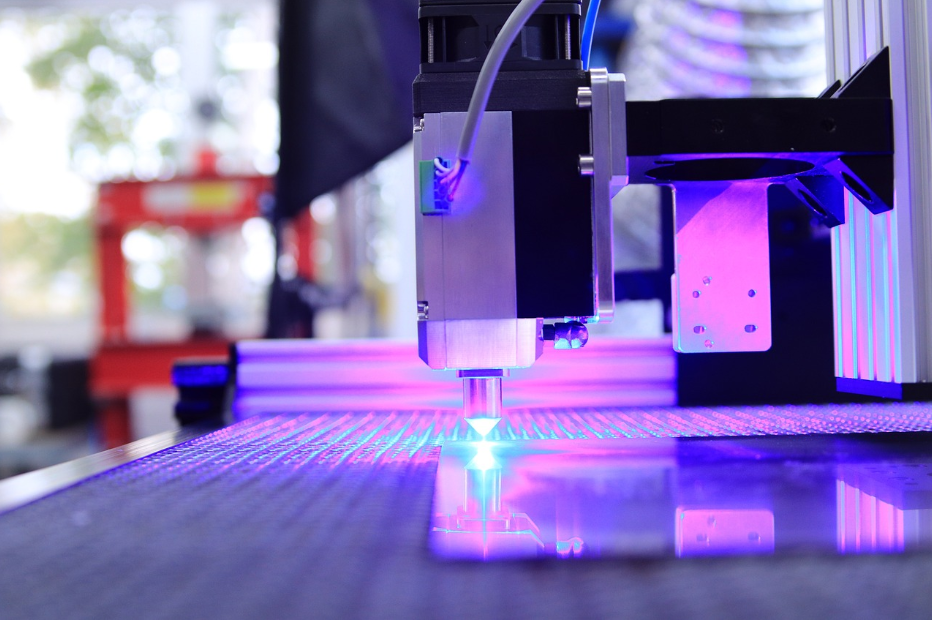

A laser cutting machine is a computer-controlled machine that employs a laser beam to cut or engrave materials with precision. Essentially, a laser is highly focused and amplified light. This beam interacts with the material, causing it to burn, melt, or vaporise locally. The materials that a laser can handle depend on the laser type and the power of the specific machine.

This guide highlights CO2 lasers and, fibre lasers which are typically used in industrial settings.

CO2 laser cutters are adept at cutting and engraving a broad array of metalic and non-metallic materials, including steel, aluminium, wood, paper, acrylic, textiles, leather, and more malleable materials.

How Does a Laser Cutter Work?

A CO2 laser cutter generates the laser beam within a tube of CO2 gas. Through mirrors and lenses, this beam is then directed towards the laser head and focused onto the material’s surface. Electronically controlled motors manipulate the laser head, allowing it to cut or engrave the predetermined shape into the material of the workpiece based on an input file that may be either a vector or raster image.

What Can You Do With a Laser Cutter?

Generally, a laser cutter can perform three key tasks: Cutting, Engraving, and Marking.

Cutting

When the laser beam fully penetrates the workpiece’s material, it produces a clean and precise laser cut. The appearance of the cut edges will vary depending on the material; for instance, cut wood often displays edges that are darker brown than the original wood, while the edges of acrylic do not change colour and retain a glossy finish after cutting. Some examples of laser cuts are 2D, 3D, screen cuts, and rotary cuts.

The width of the groove created by the laser, known as the kerf, is quite narrow. This varies from one material to another and depends on the laser’s specific settings. Typically, the kerf ranges between 0.05 mm (0.002 in) and 0.5 mm (0.02 in).

Engraving

Engraving occurs when the laser beam removes parts of the surface material without cutting through the entire thickness.

Marking

Marking happens when the laser does not remove material but alters it in some way, such as changing its colour. This is particularly common with metals when using CO2 laser cutters. A marking solution is applied to the surface of the workpiece. Once the solution has dried, the laser engraves over it. The laser’s heat causes the solution to bond permanently with the metal, creating a durable mark.

The Advantages of a Laser When Cutting

Here are the primary benefits of using a laser for cutting:

Suitable for Many Types of Materials

Lasers can efficiently handle a wide range of organic and inorganic materials more than any other cutting technology available.

No Post-Processing Required

Laser cutting is a neat process that often eliminates the need for further finishing. It can seal the edges of synthetic textiles and carpets, preventing them from unravelling. This avoids additional steps like mechanical sealing or sanding, which might be necessary with other methods depending on the material.

High Precision and Accuracy

The kerf produced by laser cutting is exceptionally small. This precision allows for the cutting of very detailed shapes and designs. Additionally, many laser cutters come equipped with integrated cameras (such as JobControl Vision) that generate registration marks and automatically adjust the cutting path if the original template shifts or distorts.

Minimal Tool Wear

Laser cutting equipment reduces maintenance costs and the need for part replacements, leading to more cost-effective operations over time.

How to Start Laser Cutting in Four Steps

If you’re keen to begin laser cutting your own designs, here’s a detailed guide on what you should consider to get started:

- Assess the Need to Purchase a Laser Cutter

- Purchasing a laser cutter isn’t necessary since there are various ways to access these machines:

- Makerspaces: makerspaces are collaborative spaces where people create and learn. They typically feature equipment like 3D printers, CNC machines, soldering irons, and often laser cutters. These spaces often provide guidance and courses on how to use their equipment and may charge a membership fee or a fee per use. Websites like makermap.com can be helpful in finding a nearby maker space.

- Educational Institutions: Schools, colleges, and universities can also be good resources for accessing laser cutters, especially for students.

- Laser Cutting Services: Another option is to use a laser cutting service, where you send your designs to the company, select your material, and they’ll handle the cutting and deliver the finished pieces to you.

- If you’re new to laser cutting, try these options before investing in your own machine. The market offers various laser cutters, including CO2 lasers, with prices ranging from around $750AUD for entry-level models to several thousand for professional-grade machines. A future post will cover more detailed information on different types and features to consider when buying a laser cutter.

- Understand What Materials Can Be Cut or Engraved

- CO2 laser cutters can work with a diverse range of materials but are unsuitable for all. Some materials may not be cut through due to their thickness or properties that might produce toxic gases or are highly flammable. The maximum thickness of material that can be cut or engraved will depend on the machine’s specifications, particularly its power, which is typically measured in watts. Standard power levels for these machines range from 30 to 10000 watts, with more powerful lasers generally reserved for industrial use only.

Following these steps will provide a solid foundation for anyone interested in starting with laser cutting, covering essential aspects from accessing equipment to understanding material compatibility:

| Material | Cut | Engrave |

Wood | x | x |

| Plywood | x | x |

| MDF | x | x |

| Cork | x | x |

| Cardboard | x | x |

| Paper | x | x |

| Leather | x | x |

| Felt | x | x |

| Cotton | x | x |

| Acrylic (Plexiglas) | x | x |

| Delrin (POM, acetal) | x | x |

| High-density polyethylene (HDPE) | x | x |

| Polypropylene (PP) | x | x |

| Granite | x | |

| Marble | x | |

| Slate | x | |

| Stone tiles | x | |

| Ceramic, Porcelain | x | |

| Glass | x | |

| Stainless Steel | x | x |

| Aluminum | x | x |

Materials that should not be cut or engraved with a laser

Certain materials should never be cut or engraved with a laser cutter as they can produce toxic gases or dust, which may pose health risks and potentially damage the machine itself. It’s crucial to be aware of these materials to ensure laser-cutting equipment’s safe and effective operation. These materials include, but are not limited to:

- Leather and artificial leather containing chromium (VI)

- Carbon fibres (Carbon)

- Polyvinyl chloride (PVC)

- Polyvinyl butyrale (PVB)

- Polytetrafluoroethylenes (PTFE/Teflon)

- Beryllium oxide

- Any materials containing halogens (fluorine, chlorine, bromine, iodine, and astatine), as well as those with epoxy or phenolic resins

Recognising and avoiding these materials is important to maintaining a safe working environment and protecting the integrity of your laser-cutting machine.

- How to create a design for laser cutting or engraving?

Most CO2 laser cutters function similarly to your typical inkjet printer. These laser cutters are equipped with specific drivers that translate an image from your computer into a format readable by the laser cutter. When using laser cutters, it’s crucial to understand the difference between vector images and raster images. Both image files can be processed; however, raster images are only suitable for engraving, not cutting.

Vector images encode lines and colours as mathematical formulas, allowing them to be scaled up without losing quality. In contrast, raster images are composed of numerous small pixels, which can lead to pixelation when the image is enlarged. Common vector file formats include SVG, EPS, PDF, DXF, DWG, CDR (CorelDRAW), and AI (Adobe Illustrator), while raster file formats include JPG, PNG, and GIF.

You can use any graphic design software, as long as you can export your design in a compatible format. Here are some examples of graphic design software:

2D Design:

- Inkscape (free, open source)

- QCAD (free, open source)

- CorelDRAW

- Adobe Illustrator

- AutoCAD

3D Design:

- Autodesk Fusion 360 (free for hobbyists and small businesses)

- Blender (free, open-source)

- FreeCAD (free open-source)

- Sketchup

- Tinkercad (free)

- Solidworks

- Onshape

Using these tools, you can create precise designs for cutting or engraving with a laser cutter, ensuring high-quality results for your projects.

General settings

When starting a laser cutting project, the first factor to consider is the size of your material and the maximum dimensions the laser bed can accommodate. This determines the largest possible size for your design. Generally, it’s advisable to configure your work area to match these dimensions.

Additionally, you should set the colour mode of your design file to RGB. Different colours within this mode are typically used to indicate different cutting or engraving processes. For instance, you might use red for all the design parts that need to be cut through and black for areas that require engraving. This colour coding helps accurately set up the laser cutter’s operations, ensuring each part of your design is processed correctly.

Creating a file for laser cutting

The machine emits a continuous beam that slices through the material during a laser cutting operation. The laser requires a vector path from the input file to execute precise cuts. The laser will effectively cut only vector graphics with the thinnest possible line thickness, which varies based on the software. Graphics with solid shapes or thicker lines typically will not be cut.

When cutting text or intricate shapes, it’s important to consider elements like the centres of letters (e.g., the inside of an “O”) that might fall out if they are not connected to the outer parts of the design. To avoid this, you might use a stencil font that connects the inner and outer parts of the characters.

Creating a File for Laser Engraving:

There are two main types of laser engraving: vector and raster engraving. Vector engraving operates similarly to cutting, except the laser power is reduced, so it only removes parts of the material without cutting through it. Raster engraving can utilise either vector files or raster images. In this process, the laser engraves the image line by line, pixel by pixel, similar to how an inkjet printer works, but instead of applying ink, the laser removes material.

Both simple shapes and complex images can be engraved. However, photographs must be converted into grayscale images before engraving to ensure clarity and detail in the final product.

- Use a laser cutter to cut.

Once your design is ready, cut it with the laser to the final stage. Laser cutters are potent tools capable of creating impressive items but pose certain risks, so a word of caution is necessary. Ensure you read and understand all the safety instructions accompanying your laser cutter. Remember, the wavelength of a CO2 laser is in the Infrared part of the light spectrum, making it invisible to the human eye. The red dot on many machines is only a positioning aid, not the cutting laser beam.

Preparation

Before starting, confirm that your material fits within the work area of the laser cutter and trim it to size if needed. Be prepared to make test cuts or engravings and have some spare material.

You don’t typically need additional tools to operate a laser cutter, but the following items might be helpful:

- Utility Knife: Useful for cutting material not fully severed by the laser or to size paper and cardboard.

- Painter’s Tape/Masking Tape: Helpful for covering the surface of your material to prevent burn marks and to secure lightweight materials.

- Measurement Tape/Calipers: Essential for measuring dimensions to ensure your final objects are correctly sized.

Settings

The key settings for a laser cutter include power, speed, frequency, and focus distance:

- Power: Controls the laser’s output power, adjustable from 0 to 100% (maximum power). Use high power for cutting thick materials and lower power for engraving or cutting thinner materials like paper.

- Speed: Affects how fast the laser head moves. For thin materials, the speed is generally set close to maximum.

- Frequency (Hz, PPI): This setting determines the number of laser pulses per second, which varies depending on the material. For instance, wood typically cuts best at 500 to 1000 Hz, while acrylic might need 5000 to 20000 Hz for a smooth finish.

- Focus: The laser head has a focusing lens inside; this focus point (where the laser beam is thinnest) should ideally be on the material surface or just below it. The required distance from the lens to the material depends on the lens type.

Many laser cutters have a motorised bed that adjusts the focus distance. In other models, you might need to manually adjust the material surface’s position.Finding the Right Settings

The laser cutter’s manual is a great starting point for determining the right settings, which often suggests settings for various materials. If you’re using a shared laser in a maker space, there are usually lists of recommended settings.

Prepare to experiment with your initial cuts. Dialling in the ideal settings for your material might take a few attempts. Change only one setting at a time during tests—begin with power and adjust in 5-10% increments. Once satisfied with the results, note down your settings for future reference.